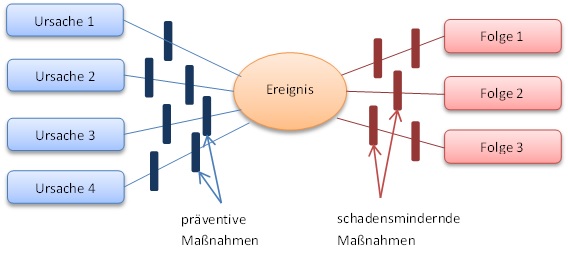

Current understanding of safe operation of plant and machinery requires a systematic approach in order to reliably identify and eliminate risks or reduce them to an acceptable level. In addition to protecting people and the environment, this also encompasses economic risks such as production outages up to the destruction of individual components or even entire plants.

The aim of systematic risk analysis is to identify and evaluate possible divergences from intended and planned functions and activities.

The outcome of systematic hazard and risk analyses results in:

- Identification of vulnerabilities

- Specific instructions for necessary modification measures

- Reliable results provided by a team of experts and traceable documentation

- Planning reliability

When a team of experts participating in an analysis is assembled, both by the operators and by the planners of a new plant, care must be taken to cover all aspects of the plant, such as: production, process engineering, electrical engineering, automation technology, chemistry, apparatus and pipeline construction, and maintenance. The analysis is led by an independent facilitator from TÜV AUSTRIA SERVICES GMBH and the outcome of the discussions is recorded by a secretary for all to see.