Testing of components and assemblies in aircraft | The largest and most powerful ICT in Austria | EMC Laboratory

Testing of components and assemblies in aircraft | The largest and most powerful ICT in Austria | EMC Laboratory

We connect research and industry. We support our customers in the development and improvement of safety and availability of their products. Our competence lies in the operation of a component testing laboratory as well as an EMC laboratory.

We offer the conception, execution and evaluation of complex mechanical and electronic tests on components and assemblies.

As part of the TÜV AUSTRIA Group and the TU Wien (Vienna, Austria), we meet the highest standards of safety and innovation to the same extent. Our tests and analyses make state-of-the-art technologies safe and competitive for the market. We guarantee this as an independent testing laboratory accredited according to EN ISO/IEC 17025.

In our mechanical testing laboratory, we offer the following services:

Material and component testing

X-rays to display external geometries in three dimensions, internal structures and defects of objects.

Download your TÜV AUSTRIA / TPA KKS ICT brochure here!

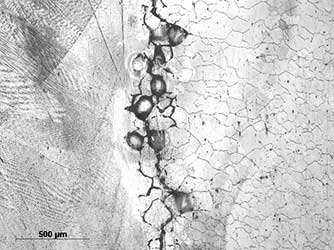

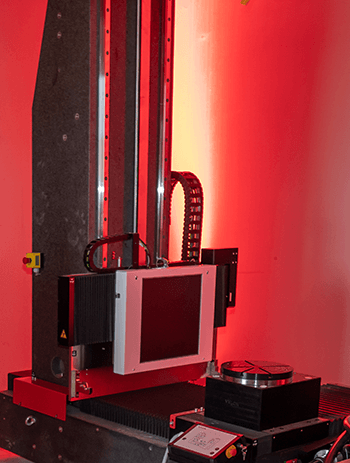

With the help of industrial computed tomography (CT), X-rays can be used not only to display external geometries in three dimensions, but also all internal structures and defects of objects.

It is also possible to track and analyse the damage behaviour of components by means of a testing machine through tension/compression in real time - this is also possible in a temperature interval. This procedure is called „in-situ CT“ (or 4D CT).

Destructive testing and in-situ CT

– Tracking crack initiation and propagation

– Tensile/compression tests with defined temperature

Non-destructive testing

– Identification and colour representation of pores,

cracks, blowholes, and inclusions

– Location, overall proportion, and manifestations of

inhomogeneities

Weld seam inspection

– Assessment of welds regarding welding defects such

as pores, binding defects, inclusions, etc.

Damage analysis

– Determination of the actual state as a 3D model

– Detection of defects

– Representation of damage areas

Assembly control

– Control of installed components

Coordinate measuring technology

– Measurement and representation in 2D and 3D

Segmentation of multi-material constructions

– Separation of different materials

Nominal/Actual comparison

– Determine the differences to technical

drawings

3D wall thickness measurement

– Analysis and colour-coded representation

Reverse engineering

– Conversion of a CT scan into a CAD model

Manufacturing geometry correction

– Corrections of tools or moulds

– Mesh compensation to eliminate deviations of

the actual geometry of additively manufactured

components

Simulation

– Component digitisation for FEM analyses

Download your TÜV AUSTRIA / TPA KKS ICT brochure here!

We carry out the tests according to your specifications on the components. We carry out all measurements, evaluate and document the results and combine them into reliable statements.

Our tests make your development cycles faster, they follow the simultaneous engineering approach and bring your simulation and measured values in line.

Dr. Joachim Rajek

TÜV AUSTRIA TVFA Prüf- und Forschungs GmbH

Gutheil-Schoder-Gasse 17 | 1230 Vienna

phone: +43-1-6650600 | joachim.rajek(at)tvfa.at