Accredited Testing Laboratory for Railway Systems

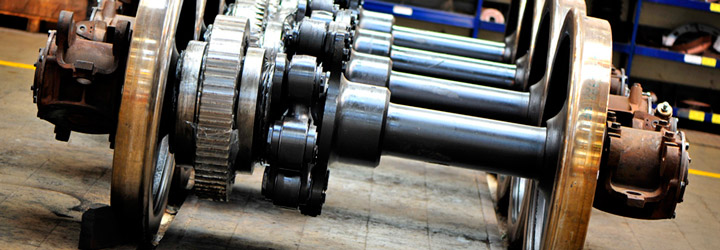

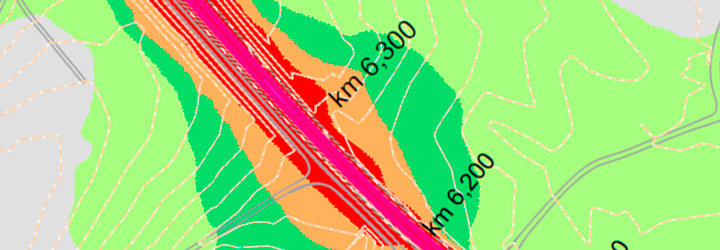

As an accredited testing laboratory for railway systems (EN ISO/IEC 17020, 17025, 17065), TÜV AUSTRIA TVFA offers independent testing of infrastructure components, rolling stock components and overhead lines. Our services include bogie testing, damping systems, ties, rail fastening systems, wheel and machine components, overhead lines and the connections and guy wires they require, as well as rails and rail joints.

We carry out complete approval tests for flash-butt and aluminothermic welded rails (EN 14587, EN 14730), for rail fastening systems (EN 13481, EN 13146) and sleepers (EN 13230, EN 16431). We also test all components and systems, such as insulated rail joints and clamping elements, according to customer specifications.

We perform fatigue and strength testing of wheelsets, bogies, frames, etc. according to EN 13749, UIC 515-4, UIC 615-4.